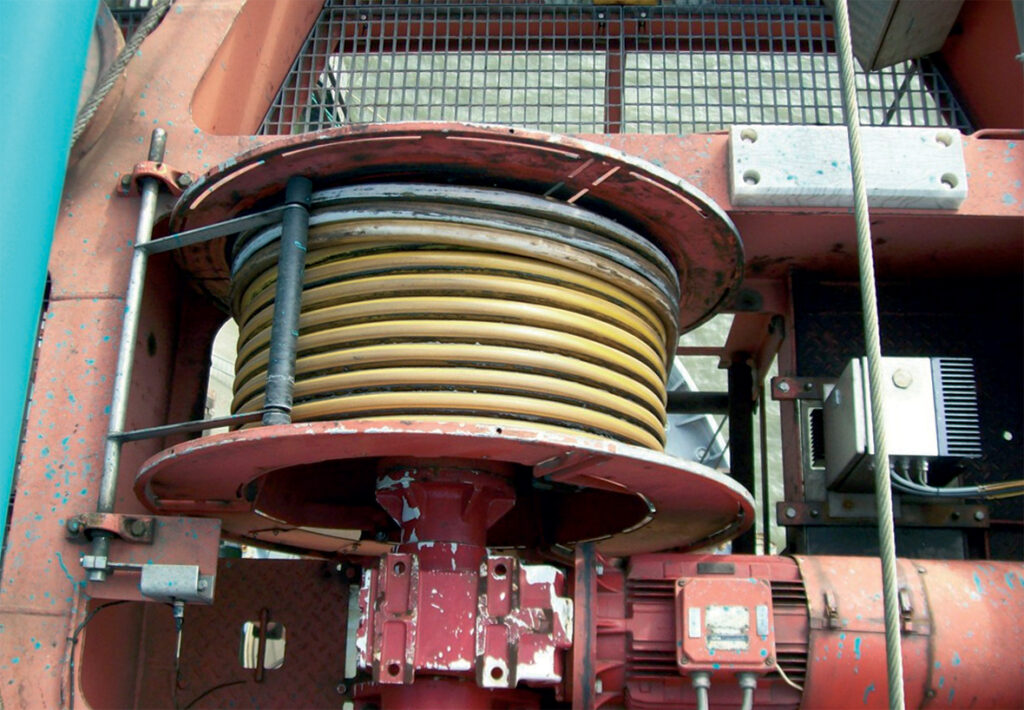

Electrical engineering, in its relentless pursuit of efficiency and safety, finds an essential pillar in medium voltage cables. These components, crucial for efficient energy transmission, possess a fascinating structural complexity.

In this detailed exploration, we will unravel the various constructive parts of a medium voltage cable, from the conductor core to the outer covering.

General Constructive Features

Conductor Core: Anatomy of Energy Transport

The conductor core, as the heart of the cable, plays a critical role in the transmission of electric current. Among the various material options are cables ranging from aluminum to copper. The choice of core material affects the efficiency and load capacity of the medium voltage cable.

Internal Semiconductor Shield

The conductive shield, often overlooked, plays a crucial role in controlling the electric field. Its importance lies in preventing interference and optimizing cable performance under varying conditions.

Insulation

Diving into the next layer, we encounter insulation. This critical component prevents current leakage and ensures the electrical integrity of the system. Dielectric insulation materials include impregnated paper, ethylene-propylene rubber (EPR), and cross-linked polyethylene (XLPE), highlighting their unique properties and applications in specific environments.

External Semiconductor Shield

The semiconductor shield appears as an essential intermediate layer. This delicately designed layer helps maintain uniformity in the electric field, avoiding discontinuities that could negatively affect cable performance.

Metallic Shield

The metallic shielding, as protective armor, shields the cable from unwanted external influences. There are various types of shielding, from aluminum tapes to copper meshes, each suitable for specific environments.

Filling and Separation: Maintaining Integrity

Internal filling and separation contribute to maintaining the cable’s structural shape and preventing deformations. We will detail the materials used and their crucial role in the long-term preservation of the cable.

Outer Covering: Protecting Against the Environment

The outer covering, the last line of defense, protects the cable against the elements. It is made of materials resistant to weather, UV radiation, and abrasion, emphasizing the importance of selecting the appropriate covering according to the installation environment.

Additional Features

Water Protection (Only OL and 2OL Type Cables)

In cables with Longitudinal Waterproofing (type -OL), a hygroscopic material tape is placed under the cover to prevent longitudinal water propagation. In Double Longitudinal Waterproofing cables (type -2OL), a series of hygroscopic material threads are also placed around the conductor.

Inner Covering or Armor Seat (Only For Armored Cables)

All armored cables have a separating cover (or armor seat) between the metallic shield and the armor. This inner cover is made of the same material as the outer covering.

Armor (Only For Armored Cables)

To enhance cable protection against external aggressions, armors are used. Their use is recommended in all installations where the risk of rubbing, impacts, and any mechanical aggression is high. Armors consist of metallic wires or strips arranged over the inner covering. Aluminum is the metal used in single-core cables.

Read more: To learn more about armored cables, click on the link.

Medium Voltage Armored Cables

In this odyssey through the constructive parts of a medium voltage cable, we have unraveled the complexities of electrical engineering. From the conductor core to the outer covering, each layer plays a vital role in the efficiency and safety of the cable. Understanding these constructive parts is essential not only for engineers but also for those who want to appreciate the technical marvel driving our modern electrical infrastructure.